Brief description of the technology solution and the added value it provides

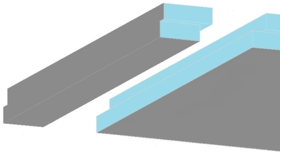

This material is an improvement of the extruded polystyrene (XPS) for the inverted flat roof. An aluminum foil covers the extruded polystyrene board, forming XPS-AL, which avoids the possibility of degenerative interactions between the extruded polystyrene board and the main waterproofing materials, enlarging the durability of them and therefore, of the inverted flat roof. This solution increase substantially the protection offered by the auxiliary separating layers usually placed to split up the XPS from the waterproofing materials. Auxiliary separating layers would not be necessary, reducing labor and material costs, and increasing the chemical protection of the inverted flat roof.

Description of the technological base

In the inverted flat roof the insulation material is placed above the waterproofing membrane, limiting the thermal variations that the waterproofing material bears up to the end of its life cycle. This constructive system is widely used, nowadays this is the most common way of setting up the materials on a flat roof.

XPS may interact under certain conditions of pressure and temperature (usual conditions for the inverted flat roof) with different types of waterproofing materials, such as PVC-P and EPDM laminas, asphalt membranes, etc.

XPS-AL consists in the adhesion of an aluminum foil on the side of the extruded polystyrene board that was to be in contact with the waterproofing material. A metallic barrier guarantees the absence of interaction between these materials. Auxiliary separating layers only cut down the interactions; XPS-AL improves the protection.

“XPS provides thermal protection to the waterproofing material in the inverted flat roof. XPS-AL adds chemical protection”

Market demands

Construction

- The inverted flat roof provides an important advantage in comparison with the warm flat roof; thermal protection to the waterproofing membrane. This protection minimizes one of the principal factors of deterioration in waterproofing membranes: thermal degradation. Nevertheless, the insulation material of the inverted flat roof (the extruded polystyrene board or XPS) presents multiples incompatibilities. Many types of waterproofing materials may interact with XPS producing deterioration in the waterproofing material.

- Sometimes, waterproofing materials are separated by auxiliary separating layers (i.e. geotextiles) from the XPS board. Geotextiles only reduce interactions; however they still occur. A metallic barrier can guarantee the absent of interaction.

“An appropriate solution for insulating the inverted flat roofs, avoiding interactions, reducing costs, and enlarging the life cycle”

Competitive advantages

- No need of placing auxiliary separating layers between XPS-AL and waterproofing membranes.

- Auxiliary separating layers suffer deterioration over time, reducing the ability of cutting down interactions, XPS-AL remain stable.

- XPS-AL is an inexpensive solution, that guaranties the absent of degenerative interactions with the majority of the waterproofing membranes.

- XPS-Al reduces labor and material costs.

- Proved functionality of the XPS-AL in extreme conditions.

- XPS-AL can enlarge the durability of the inverted flat roof in more than a 30%.

Previous references

- Extensive research activities and collaboration with industry.

- Research group oriented to technological innovation and implementation of patents.

Intellectual property

- Patent applied in Spain [P201430604]

Development stage

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

Contacto XPS-AL

Antonio Pedrosa

e:

Mercedes del Río

e:

Contacto UPM

Área de Innovación, Comercialización y Creación de Empresas

Centro de Apoyo a la Innovación Tecnológica – UPM

e: