Brief description of the technology solution and the added value it provides

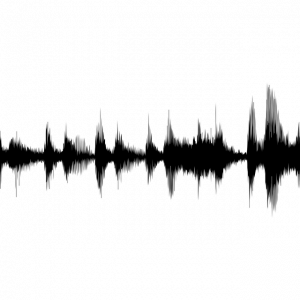

Currently the structural maintenance strategies are based on periodic time schedule inspection that are expensive and inefficiency, as it is no distinction between damage and undamaged structures procedures. It is proposed a system to interrogate an embedded fiber optic sensor network (low weigh and low intrusive) and monitor the elastic wave propagation through the structure. During any kind of damage appearance and growth, slight amplitude and high frequency elastic waves are generated and propagated everywhere in the structure. From the data of this measuring signals is possible to determine damage position and damage severity. Real time measurements allow to know the state of the structure in every moment, making possible to implement a condition-based maintenance . This technique can improve the efficiency and the time of operation, reducing financial and maintenance cost of all kind of structures.

Description of the technological base

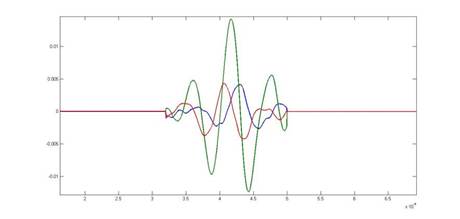

This technological solution propose a measuring system based on Fiber Bragg Grating sensors (FBGs). FBG sensors can be easily multiplexed in a single optical fiber of only 0.2 mm diameter, that can be easily embedded or mounted in a structure. Damage appearance generate a elastic wave of low amplitude (less than 0.01 microstrain) and very high frequency (between 50kHz and 1MHz). The ability of perform this measurements and process this wave signals will allow to determine damage location and damage assessment, increasing, which improves safety and maintenance costs.

“Structural damage detection by a integrated fiber optic sensor network embedded or fixed in the structure will increase the safety, reduce the maintenance costs and increase the operation time”

Market demands

- High cost of complex engineering structures require long operation time. Shorter maintenance time will reduce the cost and increase the use of the structure.

- Non destructive techniques currently employed are high dependent of operator. Integrated and atomized systems will simplify the decision making phase and the repair design.

- A integrated sensor network will increase the safety, as real time monitoring allows to detect damage in the early stage.

- The size will limit the selection of NDI procedure and the exact determination of the damage area.

- Traditional sensors require a high dense sensor network, but the implementation is extremely limited due to weigh and geometry perturbance.

Competitive advantages

- Despite that piezoelectric sensors are already used to detect elastic waves, and even it is possible to find some commercial equipments in the market, cabling weigh and external perturbances have limited its application field. The use of fiber optic sensors allows to implement this technology in all kind of structures, such as aircrafts or wind turbine blades.

- Fiber optic geometry (0.2mm diameter) and the possibility of introducing more than one sensor in the same fiber, allows to perform a high density sensor network with low perturbance and without weigh penalty.

Fiber optic sensors are also immune to electromagnetic interference, a compulsory requirement in the aerospace and energy fields. - Traditional sensors are limited by size and directionality; fiber optic sensors use this characteristics to improve damage detection.

“Maintenance based on the real condition of the structure requires an integrated sensor network that can provide the real condition of the structure in real time. This is mandatory to reduce operational cost”.

Development stage

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

Contacto Structural Fiber Sensing

Antonio Fernández-López, Alfredo Güemes, Ángel Lozano Martín

ETSI Aeronáuticos – UPM

e: , ,

Contacto UPM

Área de Innovación, Comercialización y Creación de Empresas

Centro de Apoyo a la Innovación Tecnológica – UPM

e: