Brief description of the solution and the added value it delivers

The offshore industry (civil and naval) has been cemented in recent decades as one of the main alternatives for the extraction of fossil fuels and the production of renewable energy. However, offshore operations come at a high cost both operationally and economically, which is why there is an increasing demand from this industrial sector for technologies and laboratories specialised in scale-model experimentation.

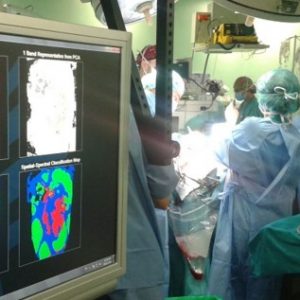

By offering more reliable testing conditions, SeaMoor optimises scale-model testing in terms of time and cost, as well as reducing the risks involved in the real installation operations and lowering chartering costs.

Results obtained with SeaMoor in experimental studies to determine the measurements of mooring lines have been extrapolated for the real installation of the Inch Cape and Moray Firth meteorological masts in the United Kingdom, and SeaMoor is also being used in the operational simulator for the gravity-based foundation system for offshore wind turbines for the European DEMOGRAVI3 project.

Description of the technological basis

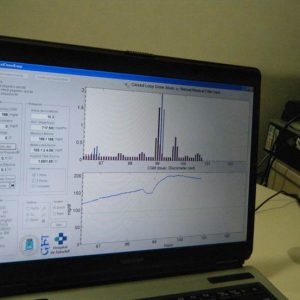

Dynamic control system for anchoring and mooring ships and marine platforms in offshore operations.

It acts as an autonomous model-scale simulator of the distortions occurring in mooring and/or anchoring lines of any kind of offshore installation or moored vessel.

It allows the characteristics of the mooring or anchoring lines (their length and tension) to be changed in real time, just as occurs in a real-scale installation, without needing to replace those lines or interrupt the process/test.

‘SeaMoor allows for greater efficiency (around 30-50%) in testing times, which implies a saving in experimental costs (around 30%) and a saving in the operating costs of the real installation, due to the use of resources that are cheaper to charter’

Business needs / application

Energy

-

The energy sector is evolving towards a reliable, affordable, publicly accepted, sustainable and competitive energy system, with the aim of reducing dependence on fossil fuels in a context of increasing resource scarcity, rising energy needs and climate change. Offshore wind energy is essential in order to achieve 100% renewable energy by 2050 and thus comply with the European commitment on energy efficiency and sustainability. To that end, the major electricity companies worldwide need to optimise their offshore operations (currently very costly) in order to make renewable energy profitable as well as clean.

Environment

-

As far as the environment is concerned, SeaMoor not only contributes to the push for marine renewables, but also optimises bunkering processes (supply of fuel from ship to ship) and makes them safer by optimising and correctly determining the measurements of mooring lines between boats during the crude oil transfer process. This prevents spillage into the sea, which, as well as causing environmental disasters, has a very high financial cost in terms of cleaning up spills and losses in the fishing industry.

‘Reducing costs in the installation of offshore wind farms is fundamental to achieving the EU’s goal of 27% renewable energy by 2030’

Competitive advantages

- Improved efficiency (around 30-50%) in testing times, reducing testing costs by up to 30%.

- More complex and thorough testing, increasing the certainty of the results.

- Lower installation/operating costs of the real installation, due to the use of resources that are cheaper to charter.

- Safer real installation operations, due to greater reliability in the reproduction of the testing conditions.

References

The measurements of the mooring lines and the operating thresholds for the real installation manoeuvre for the following projects were determined based on experimental studies carried out by SeaMoor:

-

Gravity-based foundation system for the Inch Cape offshore meteorological mast (United Kingdom). DRACE Infraestructuras S.A.

-

Gravity-based foundation system for the Moray Firth offshore meteorological mast (United Kingdom). DRACE-TYPSA.

SeaMoor has been used in the European project DEMOGRAVI3, ‘Demonstration of GRAVI3 Technology – Innovative Gravity Foundation for Offshore Wind’. H2020 http://demogravi3.com/demogravi3-project/

Stage of development

-

Concept

-

Research

-

Lab prototype

-

Industrial prototype

-

Production

Contact

SeaMoor contact

Luis Pérez Rojas, Miguel Ángel Cabrerizo Morales, Rafael Molina Sánchez

ETSI Navales – UPM

e:

e:

e:

UPM contact

Innovation and Entrepreneurship Programmes

Technological Innovation Support Centre (CAIT) – UPM