Brief description of the solution and the added value it delivers

The hydro-efficient ceramic, HidroCer, was developed to integrate into existing ventilated façade systems, in both new builds and renovations. This ceramic transpires, evaporates the liquid and is able to keep its surface temperature constant, well below the air temperature.

Nearly zero-energy buildings (nZEBs) in a Mediterranean climate need to do something about overheating in summer. This technology can keep a building’s interior at a comfortable temperature without the use of other cooling equipment and with zero emissions.

Description of the technological basis

HidroCer is a hydro-efficient ceramic that provides conventional ventilated façades with a solution to overheating in summer.

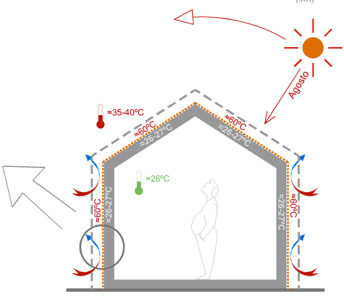

With a thickness of 2.5 cm, this ceramic is capable of regulating its surface temperature by means of transpiration and evaporation cooling. The results show that for forced air temperatures of up to 69.5±0.5ºC the surface temperature of the ceramic remains constant at 27±0.5ºC.

This ceramic can easily be incorporated into existing ventilated façade systems. With little water consumption and with no other external energy input, it succeeds in drastically reducing the current cooling demand in buildings, keeping their envelope at a close-to-comfort temperature.

‘HidroCer makes the thermal self-regulation of a building’s façade possible and can reduce its cooling demand by up to 98% in the Spanish climate’

Business needs / application

Environment

-

Reducing global CO2 emissions is an imperative [UN Framework Convention on Climate Change, Paris Agreement, December 2015]. Energy efficiency in buildings is one of the ways to achieve that reduction.

-

In Europe it has been established that, by 2020, new buildings must be nearly-zero energy buildings (nZEBs) [European Directive 2012/27/EU]. Buildings with a lower energy demand are needed in order to achieve that goal.

-

Europe is imposing stricter measures on CO2 emissions, of which buildings account for 36% of the total. [Energy Roadmap 2050, European Commission]. Among the goals set for 2030 is to improve energy efficiency by 27%.

Construction

-

The Spanish residential building stock is need of renovation: 51% of the buildings predate the NBE-79 standard, meaning that their façades are not insulated; and 48% were built before 2007 (when Spain’s Building Technical Code came into force), meaning that the thermal requirements to be met by the building envelope are minimal [data up to 2013, Ministry of Development].

-

Legislation relating to energy efficiency in buildings focuses on measures against the cold, not against the heat [CTE-DBHE]. In a climate such as Spain’s, cooling measures are necessary.

-

In climates such as that of the Mediterranean, ventilated façades overheat in summer, with the air in the chamber reaching 60-70ºC. If appropriate action is not taken in relation to the building envelope, the heat reaches the building’s interior.

‘By improving the performance of the envelope in summer with HidroCer, the goal of nearly zero-energy buildings (nZEBs) can be achieved in a climate such as the Mediterranean’

Competitive advantages

-

Thermoregulation of the building envelope. Keeping the internal temperature of the building at a comfortable level without the need to use other cooling mechanisms.

-

In the Spanish climate, the cooling demand can be reduced by up to 98%.

-

Reduction in the CO2 emissions of buildings.

-

Easy implementation in existing ventilated façades, in both new builds and renovations. Minimal thickness. Compatibility of materials and systems.

-

The heat island effect in cities is reduced by having cooler building façades.

References

-

Team with recognised experience, both in research and working with companies and public bodies.

-

Results obtained in laboratory conditions support the technology.

-

Multidisciplinary collaboration agreement with the Institute of Geosciences’ Petrology Laboratory (UCM-CSIC).

-

Collaboration with the Castellón Institute of Ceramics Technology (ITC). Funded by ‘ELIARE Network SUDOE’ (FP7/CIP).

Stage of development

- Concept

- Research

-

Lab prototype

-

Industrial prototype

-

Production

Contact

HidroCer contact

Sofía Melero-Tur

e:

UPM contact

Innovation and Entrepreneurship Programmes

Technological Innovation Support Centre (CAIT) – UPM

e: