Brief description of the technology solution and the added value it provides

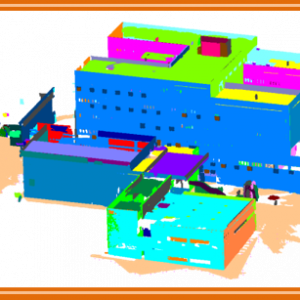

Regulatory changes proposed by the Spanish Technical Building Code (CTE) in 2007, have shown that many of the filling elements used in the construction of buildings do not meet the new thermal and acoustic requirements. As a solution, researchers from the Technical University of Madrid and the University of La Laguna propose the improvement of mortars using fine aggregates by including treated expanded polystyrene (EPSt). Thus, a lighter material with higher sound and thermal insulation properties, as well as better water vapor resistance – compared to currently used mortars-, is obtained. In addition, it increases the useful area of the building.

Description of the technological base

From the research conducted to improve thermal, acoustic and water vapor transmission properties of mortars using fine aggregates (volcanic ash) such as a pyroclastic, whose scientific name is “lapilli“. This new mortar can obtain vibrated concrete blocks that meet the requirements of the CTE regulation.

In this new mortar part of the aggregate (lapilli) has been replaced by treated expanded polystyrene (EPSt).

The material obtained is lighter, more acoustically and thermal insulating as well as water vapor resistant, than the ones used today.

“The Aridolar mortars meet the requirements of the Spanish Technical Building Code 2007 in an economically viable way”

Market demands

Construction

The entry into force of the Basic Document “DB-HR protection against noise” and “the limitation of the energy demand” under the Spanish CTE regulation in 2007, has led to an in-depth review of the thermal-acoustic properties of the filling elements used in the construction of buildings (blocks, hollow bricks, plates, panels, etc.) confirming that many of them do not meet the requirements of the regulations.

“A 5 cm panel coated with plaster on both sides, turned out to have the same sound insulation, as a wall built with vibrated concrete blocks of 15 cm thick and coated with plaster on both sides”

Competitive advantages

- Blocks, hollow bricks and panels made from this new material have remarkably improved properties including a density decrease of around 32.82%, resulting to be a lighter, and an increase of 103.64% in thermal resistance.

- Partitions and facades built with vibrated concrete blocks, would meet the CTE without having to place an interior partition (block or drywall).

- Further features: Acoustic resistance of a 15 cm wall is equal to a 5 cm panel; Flexural strength: 51.51% lower; Compressive strength: 68.85% lower; Water vapor resistance: 20.64% higher; Water vapor resistance Factor: 21.75% higher.

“The buildings built with blocks made with this new mortar will substantially increase the useful area of the building”

Development stage

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

Contacto solución tecnológica

Mercedes del Río Merino

Escuela Técnica Superior de Arquitectura

e:

Contacto UPM

Área de Innovación, Comercialización y Creación de Empresas

Centro de Apoyo a la Innovación Tecnológica – UPM

e: