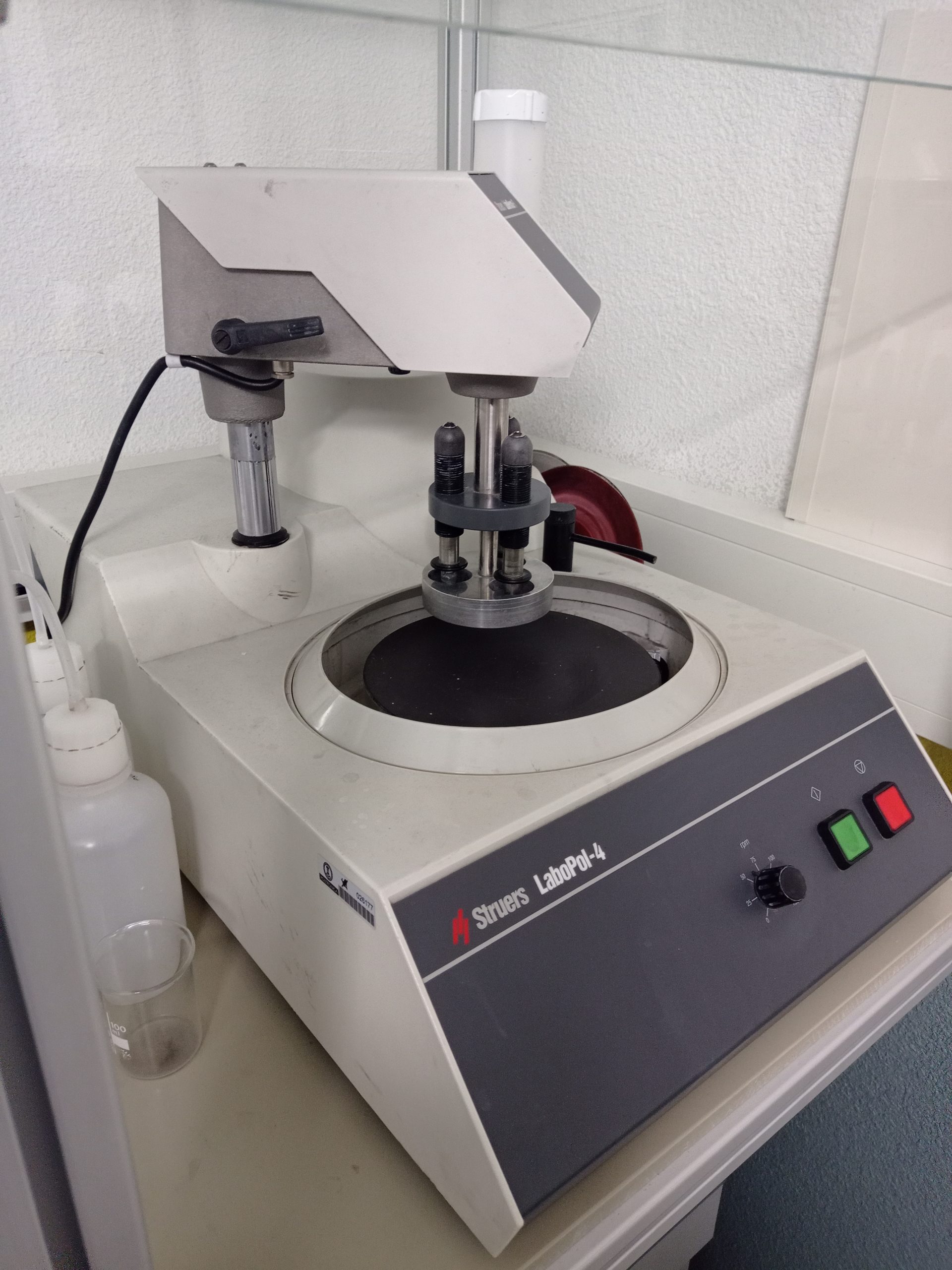

Sander/Polisher for Wafers and other materials used in electronics

The sander/polisher at the ICTS in the ISOM can sand or polish various materials used in the field of microelectronics. By changing the type of sanding, mirror-type polishing can be achieved in Wafers and on glass. The polishing pads go from tens of micron to hundreds of nanometres.

Description of the services offered

Two types of service are offered:

– Sample polishing or sanding. The user sends a sample to be polished and ISOM staff do the polishing and analyse its roughness before giving the sample to the client.

– Training needed to use the polishing or sanding equipment for any kind of user. Once the training has been given, the user can polish their samples.

Needs requested and applications

Many processes in microelectronics need a highly polished, wafer-type, surface which will be coated with a photoresist afterwards. Polishing is also critical in optical systems in order to reflect a laser, or other light source, properly.

Sector or area of application

Microelectronics, Optics.

Differential skills

ISOM staff work in a White Room where the production conditions are very strict when it comes to dust particles and impurities. Furthermore, the care taken and the quality of the polishing are of the highest quality.

Previous references for provision of services

The equipment has been used by the company MEDLUMICS to polish lasers and optical systems.

Where it is

In the ISOM. HTSE for Telecommunications Edificio C