Site card

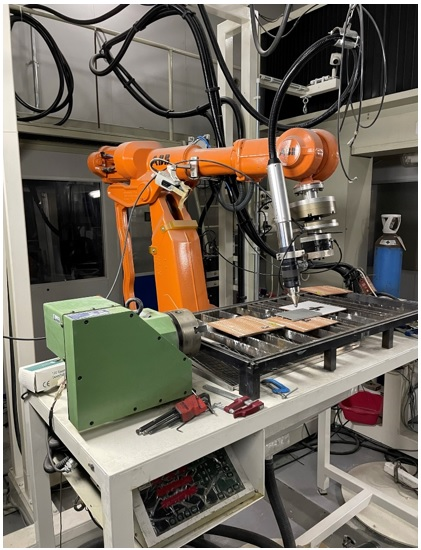

Laser cutting, welding and additive manufacturing station

Where:

Laser Centre

Ubicación:

90A.00.104.3, Centro Láser

Typology:

Infraestructura Científica

Manager: Miguel Morales

Email:

Unit equipped with a Raycus RFLC2000 2 kW fibre laser source and an ABB robotic station with different process heads (cutting, welding, hybrid laser-MIG/MAG welding, cladding).

Laser macroprocessing, hybrid manufacturing, welding, additive manufacturing

Work station for carrying out laser macroprocesses: marking, cutting, welding, surface treatments, shaping and additive manufacturing. Its main purpose is to study the industrial viability of such laser processes, as well as manufacturing one-off and short-run parts as a service to other research units or companies whose needs cannot be met by traditional workshops.

Cutting metal sheet several millimetres in thickness and welding steel and aluminium. Use by students in end-of-course projects and engineering competitions (UPM Racing and UPM Moto Student).

The purpose of this station is not so much to innovate in laser macroprocesses, since laser cutting and marking processes are widespread and available at many workshops. The cutting, welding and additive manufacturing station thus offers support and advice in the development of new industrial applications or processes that depart from the usual (whether in terms of the process or in terms of the material), drawing on the experience and know-how accumulated at the Laser Centre. The service also meets a real need in the university¿s research groups, manufacturing one-off and short-run parts on demand for use in different fields of research.